Many older Reel and Rewinding systems on Paper Machine Dry-End meet operational requirements but lack advanced safety systems, have obsolete control and drive systems, and are missing numerous upgrades that make the machines easier to operate effectively with higher quality.

SOLUTIONS

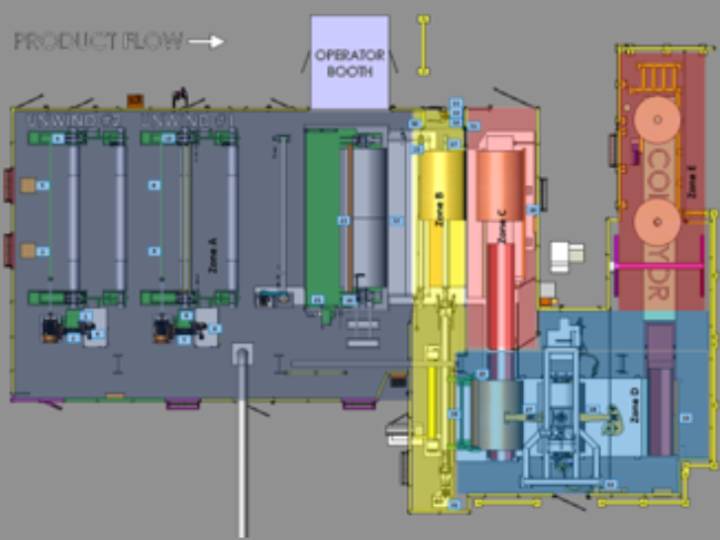

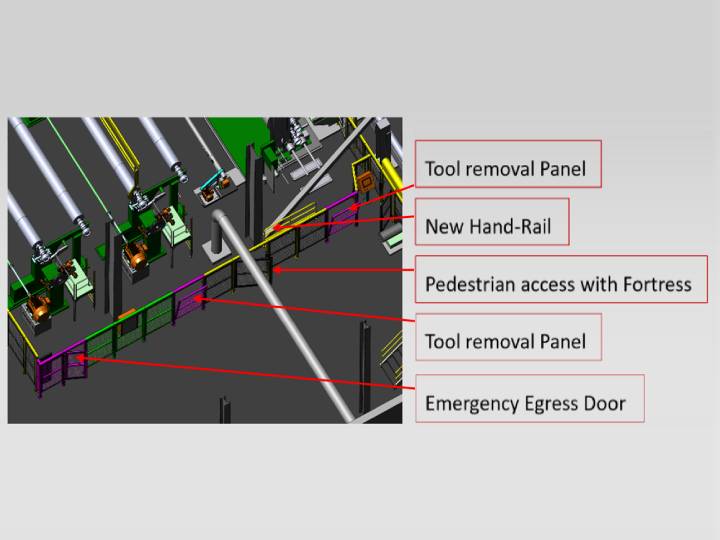

Safety is often the primary goal when commencing these projects. Just putting guarding around a machine can make it safe, but nearly impossible to operate. ProV evaluates each machine specifically to understand how the operator and maintenance personnel interact with the machine and design around these key requirements resulting in a rebuilt machine that is more effecient to operate and easier to maintain, even with new guarding and safety equipment included. Where possible, we eliminate or automate solutions to eliminate manual tasks.

Guarding Systems are the first line of defense against machinery hazards. Our guarding systems are completely engineered to fit the specifics of the application while minimizing impact on operations. Guard systems integrate cable management as well as locking and stretegically placed egress doors.

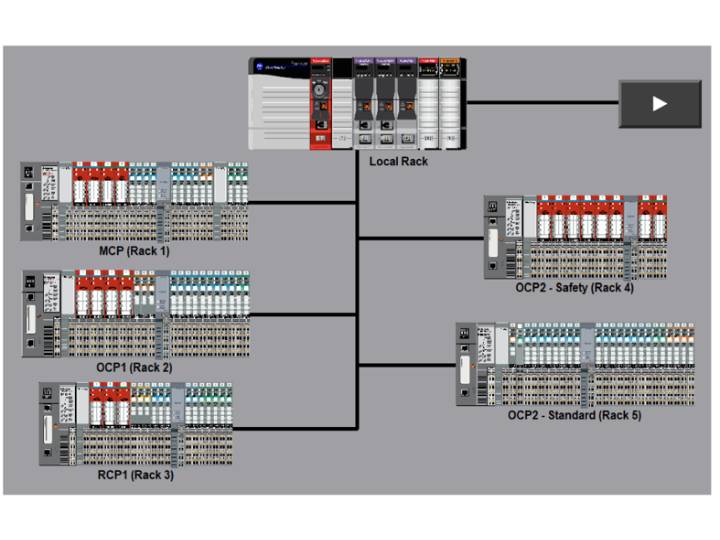

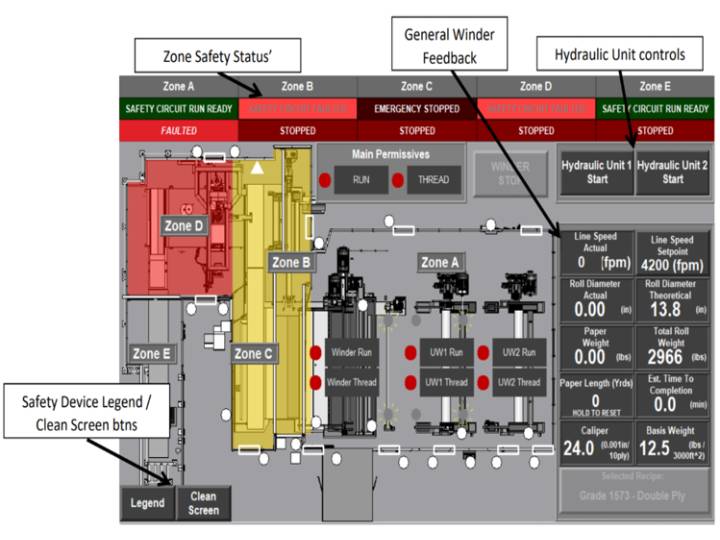

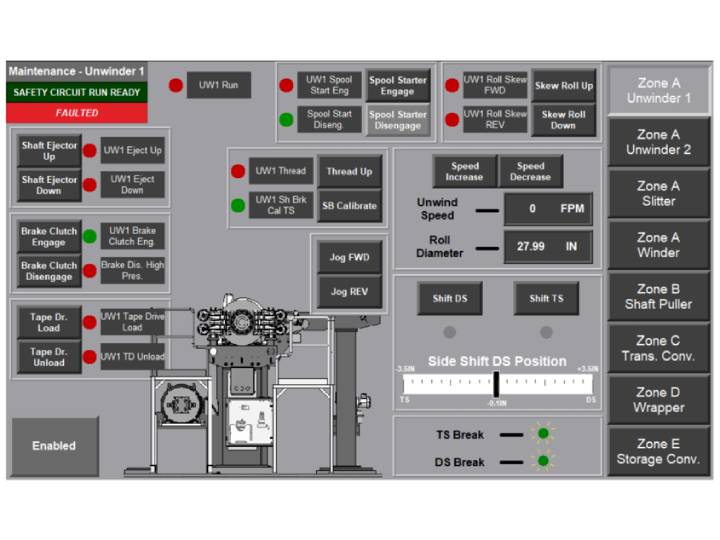

Machines can always benefit from upgrades to their control system. More accurate controls, additional automation to reduce operator interaction, detailed status feedback and alarming all allow for increased efficiency and production capability. Replacement of obsolete controls with modern drives, HMI, I/O and PLC, provide a new life to older machines.

Drive Systems are the heart of these machines and whether the drives are old and obsolete, or an original lineshaft requiring major maintenance, a new drive system will result in increased control of the web. The new drive systems operating in CIP motion reduce tension variation between machine sections, can be acceleated/ decelerated quicker, and draws between sections can be extremely accurate, all resulting in increased in productivity and reduced waste.

Upgrade to hydraulic Nip Relieving provides for accurate Roll-Build profiles. Custom P&ID and Recipe management will provide quality nip relieving for entire range of products by using Individual TD / DS Hydraulic Proportional control valves, custom Clevis Loadcells and LVDT on each cradle for accurate force and position feedback. Ultrasonic diameter sensors are also included for roll diameter verification.

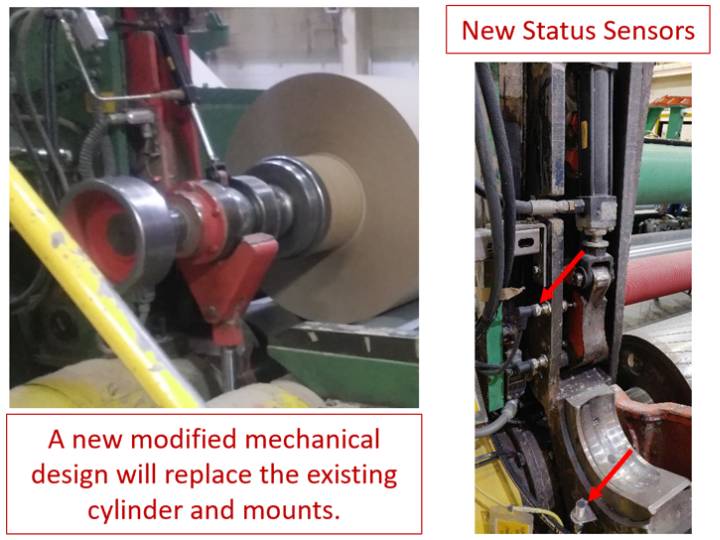

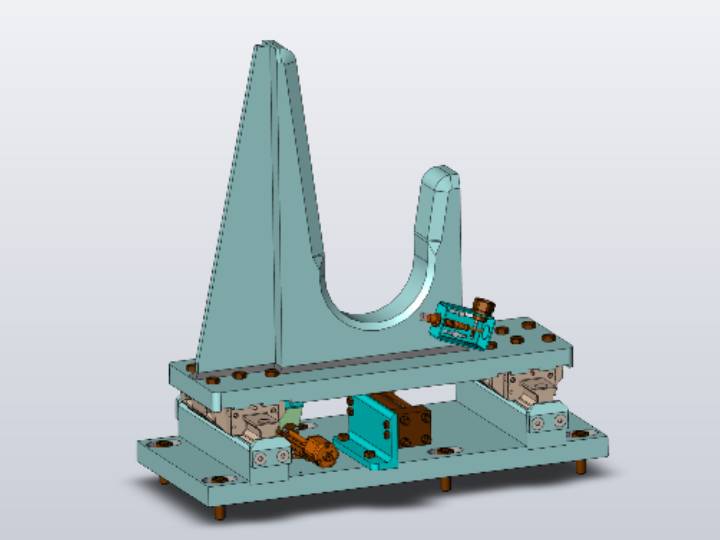

Unwind interaction with loading crane, and ability to sideshift accurately are required. ProV designs new cradles with larger bearings and load stops. Sideshift can be servo or hydraulic actuated. Centering between each set, and returning to last run posiiton reduced operator interaction.

Upgrades to the entire machine's hydraulic system allowed for proper safety separation between zones is essential to safety. Custom Designed Hydraulic Valve Stand supporting Hydraulic Safety Valves, and all valve manifolds re-using original flow controls, regulators as possible with all-new valves on manifold, and counterbalance valves at critical cylinders.